What Is Polyethylene?

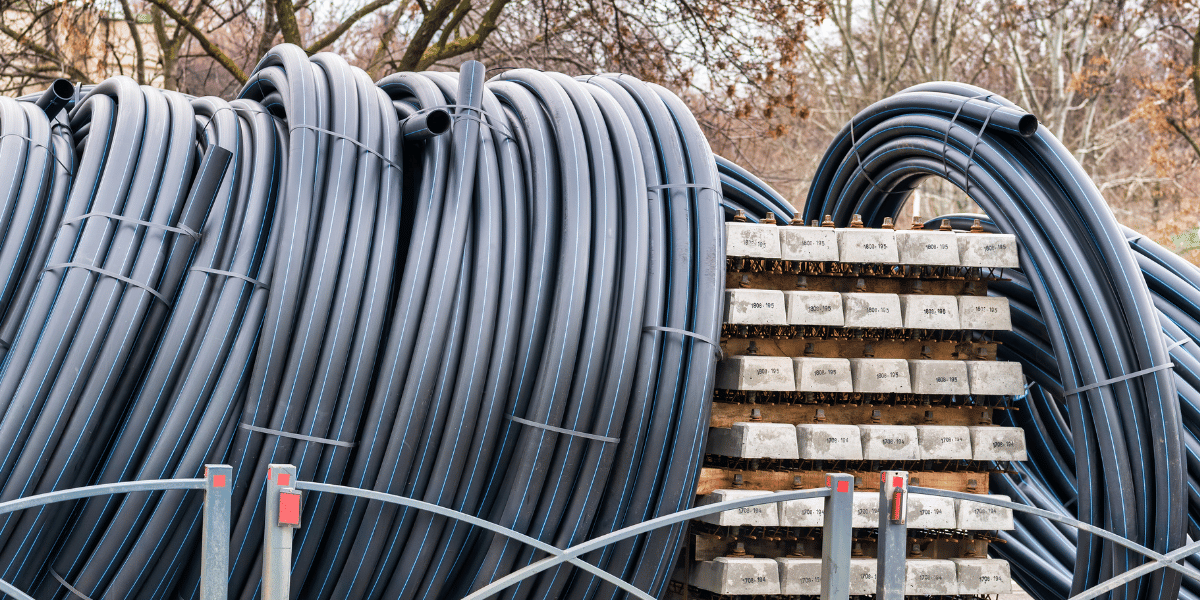

You don’t have to look far to see at least one plastic product made with polyethylene or its variants around you. Whether it's your bag, food container, water bottle, or toy, polyethylene is one of the most commonly used plastic products. You can even find it used in medical applications like knee joints. And for construction and other home project usage, polyethylene can be used for pipes, insulation and waterproofing.

What Is Polyethylene?

Polythene is a thermoplastic polymer and a member of the family of polyolefin resins. It has a variable crystalline structure and is suitable for various applications, depending on the particular type. Its durability and versatility make it one of the most attractive and preferred materials across various industries. For example, it does not chip, is resistant to fading, and remains impervious to many chemical or toxic substances, including acidic solutions. Its insulator properties also make it durable in extremely cold conditions, although it melts at high temperatures.

What Is Polyethylene Used For?

Polythene usage covers various applications, from basic household items to commercial and medical applications. Because it comes in different types, each application is based on the type used. For example, high-density polyethylene (more crystalline) is common in construction materials like fabricating drain pipes. You can also find it used as chemical containers and shampoo bottles. Low-density polyethylene has less crystalline and is commonly used in plastic packaging, from grocery bags to plastic wraps. A third type, the ultra-high molecular weight polyethylene, is more effective in high-performance applications. For example, you’ll find it used in bulletproof vests and top-quality medical devices.

What Are The Different Types Of Polyethylene?

As mentioned, the type of polyethylene determines its use or application. It comes in several categories or types, including low-density polyethylene (LDPE), linear lower-density polyethylene (LLDPE), high-density polyethylene (HDPE), and ultrahigh molecular weight polypropylene (UHMWPE).

- Low-density polyethylene: LDPE is very flexible thanks to its unique flow properties. It’s ideal for shopping bags and other applications that need flexible plastic film. It combines low tensile strength with high flexibility, so you can easily stretch it to its limits.

- Linear lower-density polyethylene: While LLDPE is similar to LDPE, you can alter its properties by adjusting its formula constituents.

- High-density polyethylene: HDPE is more robust and perfect for plastic containers, garbage bins, and cutting boards.

- Ultra-high molecular weight polypropylene: UHMWPE has a higher tensile strength, even stronger than steel. It’s used in high-performance equipment.

You’ll also find other variants like:

- Medium-density polyethylene (MDPE)

- Ultra-low molecular weight polyethylene (ULMWPE)

- High molecular weight polyethylene (HMWPE)

- High-density cross-linked polyethylene (HDXLPE)

- Cross-linked polyethylene (PEX)

- Very low-density polyethylene (VLDPE)

- Chlorinated polyethylene (CPE).

What Are The Characteristics Of Polyethylene?

Generally, polyethylene offers excellent impact and chemical resistance. It also has a lower friction coefficient coupled with near-zero moisture absorption. It is considered a thermoplastic because of how it responds to heat (by melting at extremely high temperatures). And when they melt or liquefy, they can easily solidify again.

Different polyethylene types have varying crystalline structures, affecting their tendency to soften under heat.

Why Is Polyethylene One Of The Most Commonly Used Materials?

Polyethylene has endless uses as a commodity plastic material. Product designers can design and shape them into any form they want to suit any purpose. Compared to other materials, it’s also very durable and can handle regular usage without degrading (depending on the polyethylene type).

How Is Polyethylene Made?

Like other plastic materials, making polyethylene starts with distilling hydrocarbon fuels into lighter groups known as fractions. Some of these lighter groups are mixed with other catalysts to create plastics. Different catalysts can also be used to create different polymers with particular properties.

Is Polyethylene A Toxic Material?

Despite recycling issues, polyethylene is not toxic - at least, not when it’s in its solid form. That’s why it’s widely used in the food industry for packaging, serving, storing, and handling food in different ways. However, breathing it in vapor form or absorbing it into the body in liquid form (especially during manufacturing) can be harmful.

Are There Disadvantages To Using Polyethylene?

Polyethylene is mostly considered more expensive than polypropylene (which is also usable in partly similar applications). Aside from that, the disadvantages are minor and do not deter manufacturers or consumers from using the material.

Conclusion

Polyethylene is versatile, durable, and takes a long time to break down. It’s also usable in different types for various applications, making it one of the most preferred choices for businesses and commonly used materials by individuals.

If you or your company needs to use polyethylene in your production process, it’s best to speak with a company that knows and understands the pros and cons of the material.